Rubber Covered Conveyor

Our new stock on Rubber covered conveyor has arrived, please contact us with your requirements :

Rubber Covered Conveyor

Our new stock on Rubber covered conveyor has arrived, please contact us with your requirements :

Rollers

Frames and steel rollers are made to SANS 1313 specifications and are very well priced. We call on resellers to put us to the test with our steel roller pricing. We’ll beat any quoted price, subject to stock availability.

HDPE NY roller (Nylon shaft end cap) is the most economical roller available and is built for purpose in selected applications. The tube is wholly HDPE and if unable to rotate the roller poses no threat of damage to the conveyor belt.

Roller guards fitted on the outer wing roller bracket turn any roller into an anti-size roller.

New Ceramic Sealing Products

Please contact us with your requirements for Twisted Rope, Braided Rope, Webbing Tape, Rope Lagging, Ceramic Blankets and Ceramic Cloth

Super Screw

This versatile belt fastening system allows for a join far stronger than traditional mechanical fasteners, while doubling as a permanent belt repair system. The additional strength gained from having a mechanical join imbedded in rubber conveyor material makes this fastener the perfect substitute for splicing conveyor belts (hot or cold). Especially when environmental conditions aren’t ideal for splicing hot or cold or when time saving is essential. We stock an abrasive resistant option in class 630 and class 800.

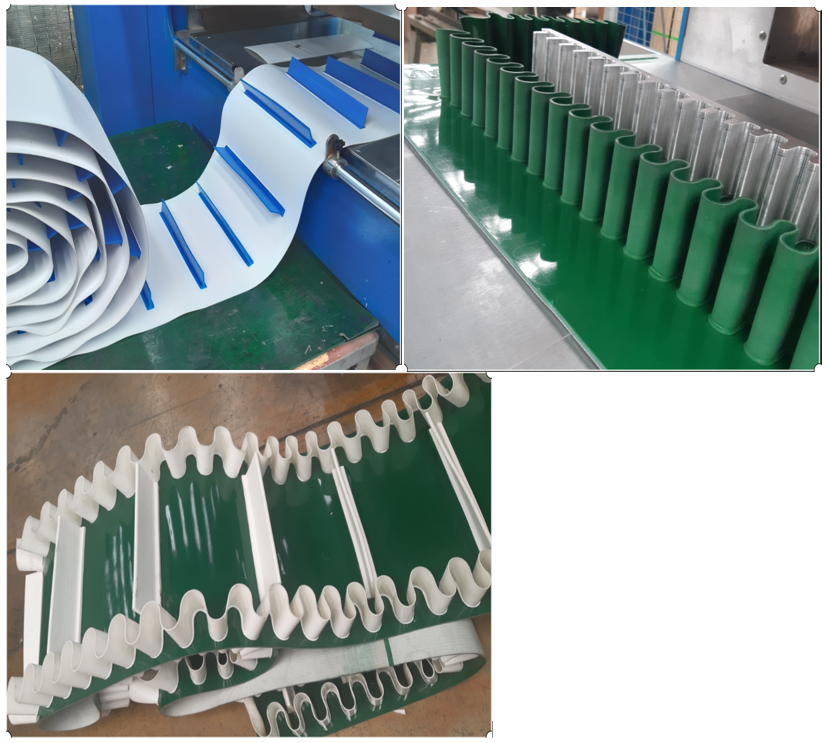

Special fabrications available on PVC/PU/TPU conveyor belts for the Food, Agriculture, Horticulture industries.

All features High-Frequency welded for exceptional built quality.

Topic : Conveyor belt trouble shooting

| Problem | Most likely cause | Likely cause |

| Belt runs to one side | Build-up on idlers | Sticking idlers |

| Section runs to one side | Join not square | Bowed belt |

| Belt runs to one side | Install training idlers | Off centre loading |

| Runs off at tail pulley | Install training idlers | Material spillage |

| Runs off at head pulley | Worn lagging | Material spillage |

| Belt slip | Insufficient traction | Worn lagging |

| Belt slip on starting | Insufficient traction | Counterweight too light |

| Excessive stretch | Improper installation | Counterweight in wrong position |

| Stripping of top cover | Incorrect skirt boards | Spanking due to load impact |

| Excessive top cover wear | Misaligned return rolls | Cover quality too low |

| Excessive pulley cover wear | Sticking idlers | Slippage on drive pulley |

| Grooving of bottom cover | Sticking idlers | Material spillage |

| Covers harden / crack | Heat or chemical damage | Improper storage / handling |

| Cover swells in spots | Oil or grease contamination | – |

| Belt failure at fasteners | Fastener plate too long | Wrong fastener type |

| Splice separation | Improper splice | Pulleys too small |

| Excessive edge wear | Off centre loading | Material spillage |

| Transverse breaks at edge | Edges folding on structure | Improper transition from trough |

| Short breaks in carcass | Impact of material on belt | Material between belt & pulley |

| Ply separation | Insufficient transverse stiffness | Pulleys too small |

| Carcass fatigue at idler junction | Improper transition from trough | Severe convex vertical curve |

| Cover blisters, sand blisters | Fine cuts in covers | Oil or grease contamination |

| Belt cupping – new belt | Excessive cover gauge ratio | – |

| Belt cupping – old belt | Oil or grease contamination | Heat or chemical damage |

Watch this space for future special offers

Belting Supply Services and BEP bestobell are expanding our footprint into Africa.

We are currently active in the following countries :

This year our sales team visited Botswana, Malawi, Mozambique, Swaziland and Namibia.

No Vacancy