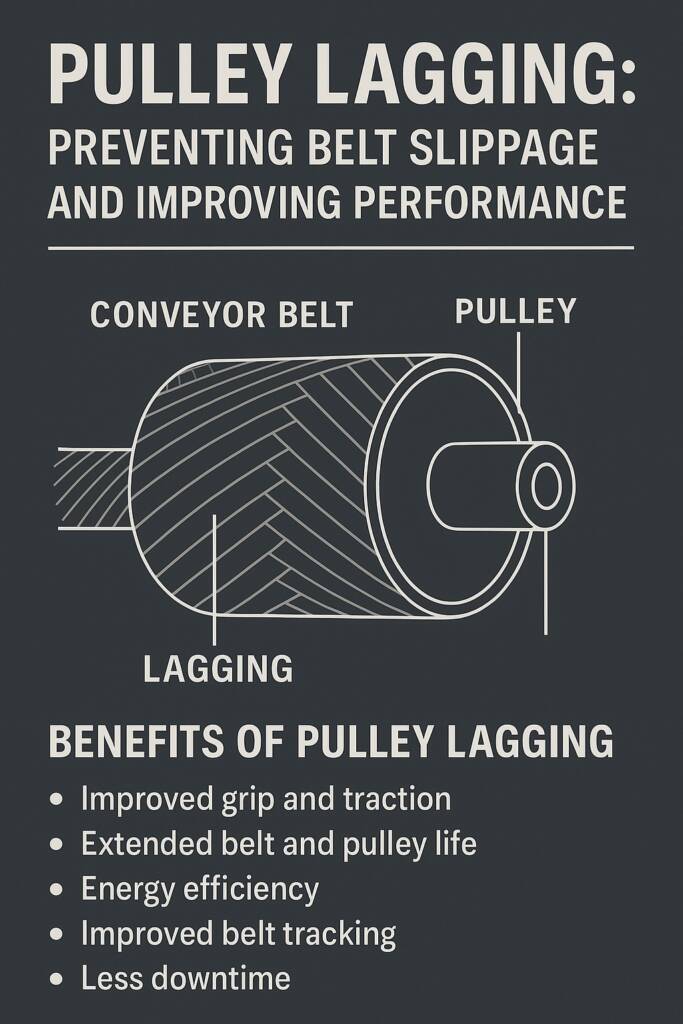

Pulley Lagging: How It Prevents Belt Slippage and Improves Performance.

What Is Pulley Lagging?

Pulley lagging is the process of applying a protective layer—usually rubber, ceramic, or

polyurethane—over conveyor pulleys to increase friction between the belt and pulley. This added grip improves traction, reduces belt slippage, and protects both components from premature wear.

What Causes Belt Slippage?

Belt slippage typically results from worn pulley surfaces, insufficient tension, contamination (dust, oil, or moisture), or incorrect lagging material. This leads to disruptions, accelerated wear, and higher energy consumption.

The Benefits of Pulley Lagging

– Improved grip & traction

– Extended belt & pulley life

– Energy efficiency

– Improved belt tracking

– Less downtime

Lagging Material Options: Which One Do You Need?

Rubber: For general industry use — cost-effective with good grip.

Ceramic: Ideal for mining and high-tension systems — durable and high-friction.

Polyurethane: Suitable for food-grade or chemical-sensitive environments — non-marking and chemical-resistant.

Why It Matters in the South African Market

Given South Africa’s rugged environments and throughput demands, downtime from slippage can be costly. Proper pulley lagging supports continuous operations and long-term savings.

How BSS Can Help

We offer on-site pulley inspections, custom lagging installations, and maintenance support to help eliminate belt slippage and improve overall system performance.